Woven Mesh

Woven mesh or woven wire cloth & fabric are products which Averinox develops and produces for a variety of applications, from filtering and sieving (filtration) to support applications.

Woven wire meshes or woven fabrics are available in many different varieties, with regard to application and specification. Many design features can be varied; for example: material, wire style/diameter(s) & mesh opening, weaving pattern, finishings like calandering, etc. Please contact us for an appropriate advice!

Woven wire mesh can be produced from several materials, for example metals like aluminum, copper, stainless steel grades (304, 304 L, 316, 316 L and 321, etc.), galvanised or plain steel, exotic alloys like Inconel ™ , Incoloy ™, Monel ™, Hastelloy ™ and Duplex ™, etc. Synthetics are for example polyester (PES), polyamide (Nylon), PVDC (Saran™), polyethylene (PE) and polypropylene (PP). See also Stainless Steel Types.

Woven wire mesh is used for our activities: General Filtration, Filtration & Separation Supports and Industrial Mesh Supports & Inlays. Woven wire mesh is also commonly used within our product groups Filters & Filter Elements and Screens & Support (Reactor Internals) and Mist Eliminators & Coaleshers (Reactor Internals)

|

Examples of heavy (coarse) woven mesh |

Fine metal woven wire mesh |

|

Examples synthetic woven mesh |

Closed synthetic woven mesh |

Crimped and/or corrugated woven wire mesh is a special type of woven wire mesh – see below on this page. We can help you in finding the right woven mesh type for your specific application. Woven wire meshes are available from stock or can be woven to your specifications. Please contact us for a personal advice!

|

Woven mesh (circular wire) |

Woven mesh (square wire) |

Square woven wire cloth is definied by the size of the aperture or mesh opening (W) and the wire diameter (d). Mesh count is the number of meshes per linear inch.

|

Closed woven heavy (coarse) mesh |

Open woven synthetic mesh (PP) |

The absolute rating is measured by the Bubble Test Method which uses alcohol as test liquid; the absolute size of an aperture or mesh opening determines the biggest ball shaped particle which can pass through the wire cloth. The correlation of this test method with the actual aperture size of a filter cloth has been proven by MPA (Dortmund, Germany 1978).

|

Hybride mesh (brass / insulated wires) |

Multifilament copper mesh |

There is no uniform method known to determine the Nominal Filter Rating of a woven wire mesh. Therefore the data often stated should be used with care. The method most commonly used is the so called Multi-Pass-Test. A test fluid, contaminated with particles of various sizes, is passed through the applied filter media under steady flow conditions.

ISO 4783-1 is the international standard for industrial wire screens and woven wire mesh:

ISO 4783-1: Generalities

ISO 4783-2: Preferred combinations for woven wire mesh

ISO 4783-3: Preferred combinations for precrimped or pressure welded wire screens

|

Open woven synthetic mesh |

Woven and pleated synthetic mesh |

Below you will find a more detailed explanation on woven wire mesh:

▪ Mesh opening w is the clearance between two adjacent warp or weft wires measured in the projected plane.

▪ Wire diameter d is the diameter of the woven wire measured before weaving.

▪ Spacing or pitch p is the clearance of the middle line of two adjacent wires or the sum of mesh width w and wire diameter d.

▪ Warp: total number of wires running parallel to the selvedges.

▪ Weft: total number of wires running at right angles to the warp wires.

▪ Mesh number per length unit n (mesh count) is the number of meshes counted consecutively in a row in a unit of length.

|

Warp direction |

||

|

Weft direction (roll width) |

▪ The unit of length can be mm, decimetres or inches, or any other unit. The number of meshes in a length of 25.4 mm is referred to as the mesh.

Mesh= Number of meshes per inch = 25.4 / p

n/cm= Number of meshes per cm = 10 / p

n/cm²= Number of meshes per cm² = (10 / p)²

▪ The Mesh opening M (for example per linear inch) can also be calculated as follows:

M = (25.4 / mesh count) – d

▪ Open screen area A0: proportion of screen openings in the total woven area as a percentage:

A0 = 100 (w / ( w+d ))²

▪ Woven weight W in kg per m²:

W = (12.7 x d²) / p

This is valid only for carbon steel as per DIN 4189 (will be replaced by ISO 4783). Conversion factors for materials other than steel (index 100) are as follows: stainless steel 101, copper 114, Monel™ metal 112.5, brass 110, phosphor bronze 112.5, nickel 112.5. For more detailed information about preferred woven wire mesh combinations see this Woven Mesh Tables and our Download Page.

Weaving pattern or texture is the way in which the warp and weft wires are linked. Many weavings patterns are possible. For example:

▪ Plain weave is the most commonly used type of weaving. Each warp wire crosses alternately above and

below each weft wire. Warp and weft wires generally have the same diameter.

▪ Twill Weave allows a thicker wire and is suitable for heavy meshes. The wire position of twill weave wire mesh is less stable compared with plain weave.

▪ Dutch Plain Weave is similar to plain weave, while the warp wires are thicker and packed more closely together. This type of woven wire mesh is mainly used as industrial filter cloth.

▪ Dutch Twill Weave is a combination of Duch Weave and Twill Weave. It is similar to twill weave, but the warp wires are thicker and packed more closely together. This type enables a strong wire cloth with super

fine filtration. Ideal for fine filtration.

▪ Five Heddle Weave has a smooth top surface and an open lower surface. It is ideal to withstand high mechanical strain and excellent filter performance.

▪ Reverse or Reinforced Dutch Weave is the same as Dutch weave except the warp and weft wires are reversed. The weft wires are thicker than the warp wires.

The opening of the two nearby orientated wires (warp wires or weft wires) at Dutch Weave is difficult to define.

Some examples of common applied weaving patterns:

|

Plain weave

|

Twill weave

|

Dutch plain weave |

Dutch twill weave |

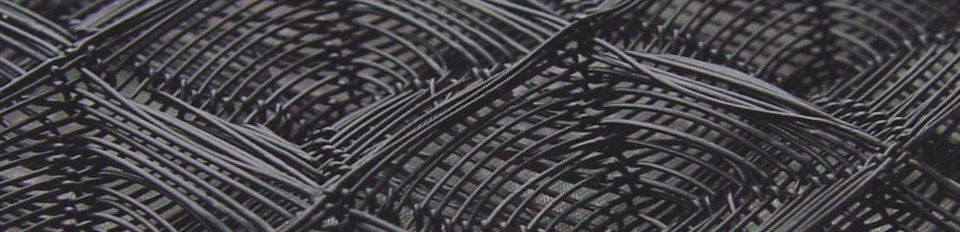

▪ Crimped and/or corrugated woven wire mesh is a special type of woven wire mesh (as per ISO 4783-3).

▪ Crimped woven wire mesh is a special type of woven wire mesh. Crimped woven wire meshes are often used as support for other filtration media, for example in vibrating screens, (high pressure) filters, grids and trays, etc. Crimped woven wire mesh can be manufactured in many styles. Common applied are for example: flat top crimped, double crimped, corrugated cimped etc.

|

Crimped woven mesh |

Crimped woven mesh |

|

Crimped & flattened woven mesh |

Crimped & flattened woven mesh |

▪ Flat top crimped woven wire mesh provides a flat surface which keeps plugging to a minium.

▪ Double crimped woven wire mesh result in a very heavy and rigid construction.

▪ Corrugated (pre-shaped) crimped woven wire mesh is provided with extra crimps in warp and weft directions. This will result in a rigid mesh, even when the mesh opening or aperture is large in relation to the diameter of the wire.

|

Detail: flat top double crimped (heavy) mesh – narrow opening |

|

Detail: flat top crimped mesh – large opening |

Materials for crimped meshes are among others stainless steel types, galvanized steel and plain steel. Applications can be found for example in the (petro)chemical industry, food & beverage industry and the mining industry. Crimped woven wire meshes are often used as support for other filtration media, for example in vibrating screens, (high pressure) filters, grids and trays, etc. See also our product groups Filters & Filter Elements and Reactor Internals / Screens & Supports

|

Crimped mesh (strip mesh) |

Crimped mesh (stripm mesh) |

▪ Calendering is a special treatment. The mesh is rolled after weaving which result in a flattened and therefore smaller mesh opening. Sintered wire mesh is compressed under pressure in an autoclave, often including filter gauze (or non-woven media) between the support layers (supports). Backings or supports are mostly heavy or coarse mesh and perforated plate. See Sintered Mesh.

|

Sintered mesh (5 layers incl. support mesh) |

Sintered mesh (incl. support perforated plate) |

Averinox has the possibility to deliver all kind of filters or separators as your specifications, based on among others woven wire mesh, see Filters & Filter Elements. More information can be found on our Download page.

Please contact us for a personal advice!

top of page

*Saran™, Inconel™, Incoloy™, Monel™, Hastelloy™ en Duplex™ are registered trade names