Stainless Steel Types

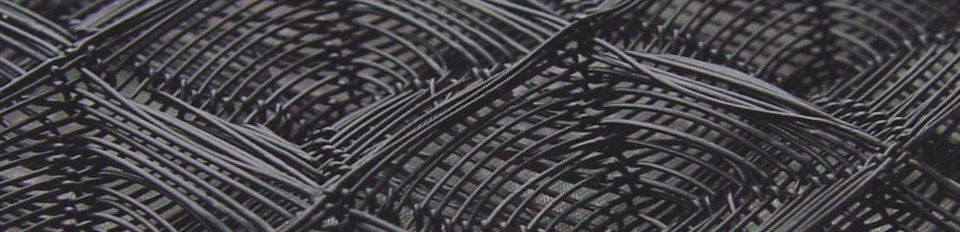

Woven wire mesh can be produced from several materials: synthetics like polyester ( PES ), polyamide ( Nylon ), pvdc ( Saran ™), polyethylene ( PE ) and polypropylene ( PP ). Metals are for example: aluminum, ( tinned ) copper, ( galvanised or plain ) steel, stainless steel grades, exotic alloys like Inconel ™ [*], Incoloy ™[*], Monel ™[*], Hastelloy ™[*] and Duplex ™[*], etc. Common applied types of stainless steel are for example: 304, 304 L, 316, 316 L and 321.

Here below you will find an explanation.

-

- 304 refers to “18-8” ( 18% chromium, 8% nickel ). 304 is the basic stainless alloy commonly applied for woven wire cloth. It withstands outdoor exposure without rusting and resists oxidation at an elevated temperature up to 800 °Cs. 304 is used in all industrial, commercial and domestic fields because of its good corrosion and heat resisting properties.

-

- Some applications include tanks and containers for a large variety of liquids and solids; process equipment in the mining, (petro)chemical, cryogenic, food, dairy and pharmaceutical industries.

-

- 304 L is very similar to 304, the difference being the reduced carbon content for better weaving and secondary welding characteristics.

-

- 316 has better resistance to pitting corrosion than the other chromium-nickel stainless steels where brines, sulphur-bearing water or halogen salts, such as chlorides are present. A valuable property of 316 is high creep strength at elevated Temperatures. 316 also possesses excellent mechanical and corrosion properties at sub-zero temperatures. Other mechanical properties and fabricating characteristics are similar to 304. Wire cloth woven of 316 has extensive use in chemical processing when better corrosion resistance is required than the regular chromium-nickel types.

-

- Because of its superior corrosion and oxidation resistance, good mechanical properties and fabricability, 316 has applications in many sectors of industry. Some of these include: Tanks and storage vessels for corrosive liquids; specialised process equipment in the (petro) chemical, food, paper, mining and pharmaceutical industries and architectural applications in highly corrosive environments.

-

- 316L is almost similar to 316, the difference being the reduced carbon content for better wire cloth weaving and secondary welding characteristics.

-

- 316Ti, the titanium-stabilised version, is used for its resistance to sensitization during prolonged exposure in the 550-800° C temperature range.

-

- 321 is a titanium-stabilised version of 304, used in particular applications within the sensitizing temperature range. Its resistance to sensitization, coupled with its higher strength at high temperature makes it suitable in application where 304 will become sensitized, or where 304L has insufficient hot strength. It is not subject to intergranular corrosion when exposed to mildly corrosive environments. However, welded 321 must never be used in highly oxidising environments.

-

- Applications: 321 is used almost exclusively for service within the sensitizing temperature range (450-850° Celcius). In welded ambient temperature applications it has been replaced by 304L. Some typical application areas are: furnace components, superheater parts and expansion bellows.

Please find more information here: Downloads.

*Saran™, Inconel™, Incoloy™, Monel™, Hastelloy™ and Duplex™ are registered product names of their respective trademark holders.