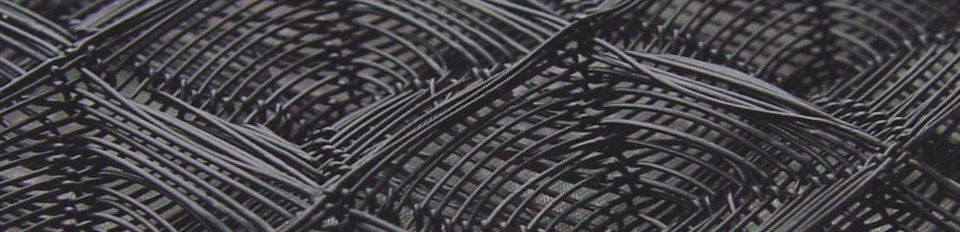

Spiral Belts

Averinox spiral belts are mostly applied in transportation and filtration or separation applications for waste water treatment, in municipal plants, private plants, etc. A spiral belt, also called (spiral fabric, link fabric or belt filter) is the ideal solution for dewatering cases.

A long experience in the field of industrial fabrics and a constant attention to ecology have allowed Averinox to develop a wide range of spiral mesh belts for mechanical dewatering of liquid to solid for any kind of material.

Averinox has a 24-hour service facility available that can provide immediate assistance, supply and/or mounting of metal conveyor belts.

|

|

|

|

A belt press (front view) |

A belt press (side view) |

– Our product range covers all sludge belt press liquid filtration applications, such as:

– Dewatering of inert sludge from quarries or mines

– Dewatering of biological or chemical sludge from municipality sewage plants

– Pressing of grapes, fruit and others

Averinox spiral belts are also used at critical stages of Particle Board, Medium Density Fibreboard (MDF), Oriented Strand Board (OSB), Hardboard & Wood Veneer processes and for the manufacture of ceiling tiles, etc.

|

|

|

|

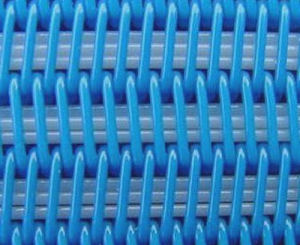

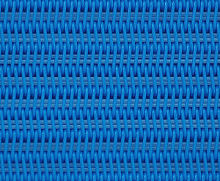

An example of a spiral belt |

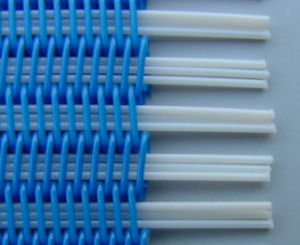

A spiral belt with 3 filing wires |

Averinox Spiral belts are made with special first quality yarns in 100% polyester. Every Averinox spiral belt is heat-set granting a high degree of stability and long running life. Advantages of our spiral belts are among others: strength, flat surface, good air permeability, stable property against heat and moisture, low thermal shrinking, less elongation at heat and a long lifespan.

Spiral belts are connected spirals by use of cross wires. The spirals contain filling wires, through which the open area is determined.

|

|

|

|

Schematic layout spiral belt |

|

Features & Benefits:

– High strength

– Stable under high tension

– High resistance against abrasion

– Can be made on size on site

– Seamless – the seam has exactly the same strength of the belt

– Can be repaired easily on site

– Durability, smoothness and good dirt release

– Filled or unfilled to achieve different filtration characteristics (Air permeability: 250 to over 1000 CFM)

– Sealed edges for lasting, economical solutions

– Widths up to 6 linear m

– Standard lengths to 60-80 m

– pH range 2 to 8

A range of PES filled and unfilled qualities are manufactured. Below you can find an overview of our most applied spiral belts:

|

|

|

|

|

Spiral belt type psb 15/50 |

Spiral belt type psb 21/66 |

Spiral belt type psb 29/85 |

| Spiral wire diameter 0.9 mm Cross wire diameter 0.9 mm Filling wire diameter 0.8 mm 15 spiral wires per 10 cm lenghtwise 55 spiral wires per 10 cm crosswise Air permeability 470-1075 CFM* Weight 1,530-2,600 kg/m2 Thickness 3,0 mm |

Spiral wire diameter 0.7 mm Cross wire diameter 0.9 mm Filling wire diameter 0.8 mm 21 spiral wires per 10 cm lengthwise 66 spiral wires per 10 cm crosswise Air permeability 400-1000 CFM* Weight 1,350-1,850 kg/m2 Thickness 2,5 mm |

Spiral wire diameter 0,55 mm Cross wire diameter 0.9 mm Filling wire diameter 0.8 mm 29 spiral wires per 10 cm lengthwise 85 spiral wires per 10 cm crosswise Air permeability 375-940 CFM* Weight 1,170 – 1,600 kg/m2 Thickness 2,1 mm |

Depending on your project we can supply for example different yarn materials, flat spiral yarns and flat stuffers.

|

|

|

|

A spiral belt with a flat spiral wire |

A spiral belt with a flat filling wire |

Please find more information here: Downloads.

*CFM : air quantity flowing through spiral belt in Ft3 / Ft2 / hour at a pressure difference of 127 Pa

top of page