Perforated Media

Averinox supplies perforated media like plates and screens for a variety of applications. Perforated plates are used in a number of different applications for a variety of reasons. Perforation will be obtained by punching and optionally stretching. In addition ,very small holes can be realized, with the aid of electro-chemical machining.

Used mostly as a screen, filter, shield, and guard, perforated materials can control the passage of air, liquid, light, solids, heat, electromagnetic waves, and sound waves. Supplied either fully perforated or with margins and/or blank areas, perforated sheet can be produced to meet your design and production requirements. Available materials are among others: 304, 316, 310s (drilled and milled plate), Inconel ™, Incoloy ™, Hastelloy ™, Monel ™, Duplex™, Titanium, brass, copper, aluminium and bronze.

Perforation can also be obtained by drilling and/or milling. Using this special method, hole sections can be step-drilled, cylindrical and conical. Hole diameters may vary from 0.8 to 12 mm. Plate thickness amount to 20 mm. Specific surfaces can be obtained by among others sand-blasting or polishing. This type of perforation is mainly used in the food industry, pulp & paper industry and chemical industry in for example the process of dewatering slurries.

Perforated plates or media are primarily used within our activities: General Filtration, Filtration & Separation Supports and Industrial Mesh Supports & Inlays. Perforated plate is for example also used within our product groups: Filters & Filter Elements and Screens & Supports (Reactor Internals)

Typical perforation patterns can be found at: Perforation Patterns.

|

||

|

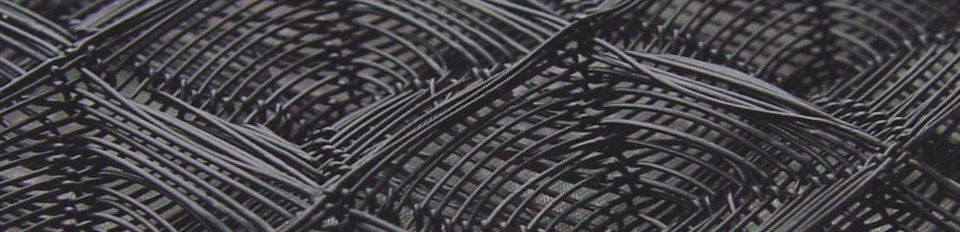

Punched Plate; circular perforation & slotted perforation

|

|

Milled Plate; cylindrical & conical holes

|

Available materials are among others: stainless steel types like 304, 316, 321 (see Stainless Steel Types), Inconel ™, Incoloy ™, Hastelloy ™, Monel ™, Duplex l™, Titanium, and non-metallic materials such as brass, copper, aluminium-bronze and synthetic materials.

Averinox’s specialities are critical perforation patterns, particular perforated areas and shapes on stainless steel material: very close perforations and hole diameters, equal, and in some instances even smaller than the plate thickness.

Below are some examples of very critical perforation patterns, including relatively dense perforations and (very) small hole diameters in thin and thick plate. The hole diameter can be smaller than the plate thickness.

|

Punched perforation, slotted holes in 0,7 mm thick plate [mm]

|

|

Punched & stretched perforation (holes in <0,5 mm sheet) [mm]

|

Such critical applications can be found among others in the food processing industry, paper industry and (petro)chemical industry.

|

Drilled perforation, tiny holes in 10 mm thick plate [mm]

|

|

Electrochemical perforation, holes in really thin sheet [mm]

|

More general information can be found on our Download Page. Common perforation patterns can be found here: Perforation Patterns More information on Stainless Steels can be found here: Stainless Steel Types. Please contact us for a personal advice to your specific situation.

top of page

*Inconel™, Incoloy™, Monel™, Hastelloy™ en Duplex™ are registered trade names

![Punched perforation, slotted holes in 0,7 mm thick plate [mm] Punched perforation, slotted holes in 0,7 mm thick plate [mm]](http://www.spirofil-averinox.com/wp-content/uploads/prpl111.jpg)

![Punched & stretched perforation (holes in <0,5 mm sheet) [mm] Punched & stretched perforation (holes in <0,5 mm sheet) [mm]](http://www.spirofil-averinox.com/wp-content/uploads/prpl101.jpg)

![Drilled perforation, tiny holes in 10 mm thick plate [mm] Drilled perforation, tiny holes in 10 mm thick plate [mm]](http://www.spirofil-averinox.com/wp-content/uploads/prpl121.jpg)

![Electrochemical perforation, holes in really thin sheet [mm] Electrochemical perforation, holes in really thin sheet [mm]](http://www.spirofil-averinox.com/wp-content/uploads/prpl8a1.jpg)