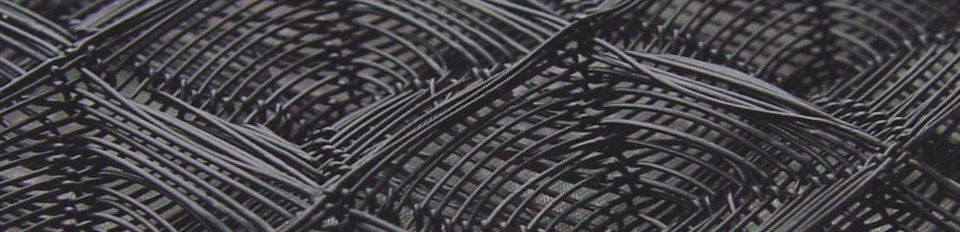

Knitted mesh

Knitted wire mesh or cloth has a typical structure. These meshes, thanks to their great ductility, allow for making bodies of quite different geometry and density. It grant a good distribution of pressure. This physical and technical quality make them suitable to meet a wide range of (industrial) applications. Specific knitted structures are also called technical textiles.

|

|

||

|

Knitted Metal Mesh |

Knitted fabric can be composed from synthetics or metals. Materials that can be used for knitting are for example: Nylon™[*], polypropylene ( PP ), (high desity) polyethylene ( PE ), polyester, aluminium, (tinned) copper, ( galvanized or plain / mild) steel, many stainless steel grades ( 304, 316, 321 ), exotic alloys like Inconel ™[*], Incoloy ™[*], Monel ™[*], Hastelloy ™[*] and Duplex ™[*], etc.

Knitted structures consists of wires of various materials or combinations of other materials that have been knitted into a mesh structure. The knitted structure produces a matrix of interlocking loops that can move relative to each other in the same plane without distorting the mesh.

|

|

||

|

Schematic layout knitted mesh (2-D)

|

Each loop is actually free to move in three directions, and the finished knit permits two-way stretch. Also, each loop can act as a small spring when subjected to compressive stress. Thus, compressed knitted wire mesh yield to shock or vibration stresses, but immediately resume their original form when the force is relieved.

Calandered knitted mesh is a rolling process which decreases open area.

Many knitting styles are possible; Averinox delivers mostly as your application and derived specification.

|

|

|

|

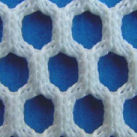

Knitted Mesh (example of a ‘style’) |

Knitted Mesh (example of a ‘style’) |

|

|

|

|

Knitted Mesh (example of a ‘style’) |

Rolled Knitted Mesh (example of a ‘style’) |

Knitted wire mesh can be made from any material that can be drawn into wire form or shape. Synthetic fibers, plastics and other materials can be co-knitted with one another to enhance product capabilities (strength, thickness, etc.), surface conditions and filtration characteristics. These materials can be knitted for example in parallel with a metal wire, thus increasing its effective surface area, which is an important characteristic in entrainment separation. In such cases, the metal wire acts as a structural support and binder.

|

|

|

|

|

|

Knitted Mesh |

Knitted Mesh

(polyester) |

Knitted Mesh

(polyester) |

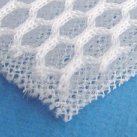

Knitted Spacer Mesh

(3-D, polyester) |

Applications for knitted wire mesh in the industrial field are numerous:

– Reïnforcement or support in composite materials: to reïnforce and give structure to components like

non-wovens, tubbing applications, rubber, tapes etc.

– Entrainment separation / gas-liquid separators: generally applied to remove droplets carried by vapour

streams in order to reduce the loss of expensive products, prevent the corrosion of downstream

equipment, increase product purity, etc. Applications can be found in among others the (petro)chemical

industry.

– Spacing: to create a constant distance in between components like filters, membranes. Applications can

also be found in seat and bed cushions. See also Knitted Spacer Fabric. Flow aids: enables and facilitates the flow of resin into a mould. application in industries were composites are processed and shaped.

– Protection: to keep persons and body parts out of machines.

– Signalisation: to indicate dangerous areas or to indicate location of cables/pipes etc.

Other industrial applications (mainly metal knitting structures) are for example gaskets, sealings, expansion joints, electronic EMI/RFI, shielding, power cable splicing, shock and vibration absorbing, etc.

Averinox has experience and is in position to deliver all kind of filters or separators as per your specifications, based on among others knitted mesh, see Filter Elements.

More information can be found here: Downloads.

* Nylon™, Inconel™, Incoloy™, Monel™, Hastelloy™ and Duplex™ are registered product names of their respective trademark holders.