News

News about Averinox is displayed on this page. Take a look at our news articles.

March 2014: Averinox has been officially certified by Kenteq

Averinox has been officially certified by Kenteq, the knowledge and advice organization of technical craftsmanship, as a training company within the cluster engineering / mechatronics. We now have our first apprentice mechanic to work!

Averinox has been officially certified by Kenteq, the knowledge and advice organization of technical craftsmanship, as a training company within the cluster engineering / mechatronics. We now have our first apprentice mechanic to work!

February 2014: Averinox receives maintenance contract Waterschap Scheldestromen

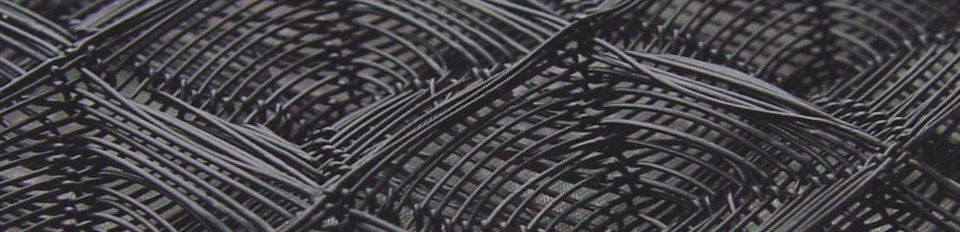

Averinox receives service contract for maintenance of 4 wastewater treatment plants of Waterschap Scheldestromen. The maintenance program includes regular maintenance and calamity service of sieve belt presses and dewatering tables. More information in this area can be found here: Maintenance, Advice & 24h Service

Averinox receives service contract for maintenance of 4 wastewater treatment plants of Waterschap Scheldestromen. The maintenance program includes regular maintenance and calamity service of sieve belt presses and dewatering tables. More information in this area can be found here: Maintenance, Advice & 24h Service

January 2014: Renewal Quality System 9001-2008 by TÜV.

Averinox has been certified last December by TÜV, following the EN-EN-ISO 9001:2008. Our former ISO 9001:2000 quality system has been completely updated and includes now also the Dutch VCA standard. VCA means Safety, Health and Environment Checklist for Contractors, but it is much more than that. VCA is a complete programme whereby service-supplying companies may be tested in a structured and objective manner, and certified for their safety administration system.

January 2013: Cooperation with Solids Technology from Ireland

Averinox provides service to installations of all known manufacturers. An example of a succesful collaboration is Solids Technology from Ireland. Solids Technology engineers and manufactures complete systems for dewatering applications. This cooperation has already been successful in several projects. Averinox directs the project, during the installation / assembly on location of the customer. Averinox installs all systems and provides after completion the regular maintenance including 24-hour service during failures. This cooperation is now oficially and is expanding to other areas outside the Netherlands. Additionally, Averinox, can also advise in the delivery of new equipment to their clients. More information can be found here on our website.

Averinox provides service to installations of all known manufacturers. An example of a succesful collaboration is Solids Technology from Ireland. Solids Technology engineers and manufactures complete systems for dewatering applications. This cooperation has already been successful in several projects. Averinox directs the project, during the installation / assembly on location of the customer. Averinox installs all systems and provides after completion the regular maintenance including 24-hour service during failures. This cooperation is now oficially and is expanding to other areas outside the Netherlands. Additionally, Averinox, can also advise in the delivery of new equipment to their clients. More information can be found here on our website.

Below you will find some examples of the standard program for belt presses of Solids Technology. More information about Solids Technology can be found here.

May 2012: Averinox joined officially the 7th Framework Programme Regarding European R&D projects

The main objectives of FP7: Specific programmes: Knowledge lies at the heart of the European Union’s Lisbon Strategy to become the ” most dynamic competitive knowledge-based economy in the world”. The ‘ knowledge triangle’ – research, education and innovation – is a core factor in European efforts to meet the ambitious Lisbon goals. Numerous programmes, initiatives and support measures are carried out at EU level in support of knowledge. The Seventh Framework Programme (FP7) bundles all research-related EU initiatives together under a common roof playing a crucial role in reaching the goals of growth, competitiveness and employment; along with a new Competitiveness and Innovation Framework Programme (CIP), Education and Training programmes, and Structural and Cohesion Funds for regional convergence and competitiveness. It is also a key pillar for the European Research Area (ERA). FP7 is the short name for the Seventh Framework Programme for Research and Technological Development. This is the EU’s main instrument for funding research in Europe and it will run from 2007-2016. FP7 is also designed to respond to Europe’s employment needs, competitiveness and quality of life. Averinox joins actually a program regarding Energy out of Biomass. See www.logistecproject.eu See Waste flows are turned into fuel by TORWASH (news item by ECN)

The main objectives of FP7: Specific programmes: Knowledge lies at the heart of the European Union’s Lisbon Strategy to become the ” most dynamic competitive knowledge-based economy in the world”. The ‘ knowledge triangle’ – research, education and innovation – is a core factor in European efforts to meet the ambitious Lisbon goals. Numerous programmes, initiatives and support measures are carried out at EU level in support of knowledge. The Seventh Framework Programme (FP7) bundles all research-related EU initiatives together under a common roof playing a crucial role in reaching the goals of growth, competitiveness and employment; along with a new Competitiveness and Innovation Framework Programme (CIP), Education and Training programmes, and Structural and Cohesion Funds for regional convergence and competitiveness. It is also a key pillar for the European Research Area (ERA). FP7 is the short name for the Seventh Framework Programme for Research and Technological Development. This is the EU’s main instrument for funding research in Europe and it will run from 2007-2016. FP7 is also designed to respond to Europe’s employment needs, competitiveness and quality of life. Averinox joins actually a program regarding Energy out of Biomass. See www.logistecproject.eu See Waste flows are turned into fuel by TORWASH (news item by ECN)

December 2011: Averinox participates in Energy from Biomass (Toripo project)

Averinox participates in obtaining energy from Biomass resources. The TORWASH process removes 99 % of salts from wet and saline biomass like reed, grass, leaves and digested manure and increases the caloric value of the biomass. The product of the TORWASH process, a pressed pellet (see picture below) can be used in regular incineration or power plants for energy generation without negative effects.

Fuel pellets from mowed grass, produced in the laboratory scale

Fuel pellets from mowed grass, produced in the laboratory scale

Essential for the TORWASH process is the treatment of the biomass in presence of water with a higher pressure and temperature. After TORWASH the water can be pressed out of the biomass mechanically, after which the product is suitable for incineration. The biggest gain of TORWASH is that thermal drying of the biomass is not necessary anymore before incineration. With TORWASH wet and fibrous biomass can be processed. Without TORWASH, this biomass can not be mechanically dewatered because the water is chemically and biologically bound in the biomass. Also, the biomass is resilient and can not be pressed. Another aim of the TORWASH process is to wash out the salts present in the biomass. The reactions during the TORWASH process remove the salts from the biomass, so that they can dissolve in the water. With this salt removal, the biomass becomes suitable for incineration, because corrosion and bed agglomeration caused by high salt content no longer occur during the incineration process. The Torwash process is proved on a laboratory scale at the Dutch Energie-Onderzoek Centrum Nederland (ECN).The TORIPO project has started in september 2010. Coming 3 years a consortium consisting of ECN, Averinox, Triqua and LEAF will develop a pilot installation for the Torwash project. Within this collaboration, Averinox engages in the dewatering of the wastewater, which is produced during the TORWASH process. Special equipped dewatering equipment will be developed and applied for this project.

Company information

Averinox B.V.

Rode Ring 49N

1566HR Assendelft

The Netherlands

T. +31 (0)75- 890 8700

E. mail@averinox.com