Sintered Mesh

Averinox develops and supplies sintered wire mesh (and sintered non woven media) used for fine, deep or sub-micron filtration. Common applied materials are stainless steel types 304L and 316L. Exotic alloys can be delivered on requist. Sintered woven wire mesh and non woven sintered web can be in used for several filtration applications in for example the petrochemical and chemical industry, water conditioning and pharmaceutics.

Sintered mesh is mainly used in our operations: General Filtration, Filtration & Separation Supports and Industrial Mesh Supports & Inlays. Sintered mesh is also used in our product groups: Filters & Filter Elements and Screens & Supports (Reactor Internals)

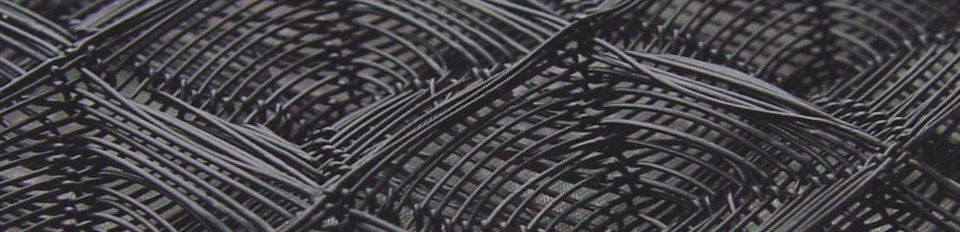

Filtering, washing and drying in one step, for example, is a typical application. Sintered woven wire mesh consist of multi-layers of woven wire mesh laminated together by use of ‘ sintering ‘. This creates an enormous class of new materials with a very wide variety of mechanical properties. By combining multiple layers of different mesh weavings, it is possible to design materials with specific target thickness, permeability, pore size, and mechanical strength. Some layers are used for high precision filtration, others for protecting and reinforcing.

|

Sintered cylinder (several mesh layers) |

Sintered cylinder (metal particles) |

Sintered wire mesh is produced by a series of technical processes. Precision woven wire mesh is uniformly calendered (roller flattened) to ensure good contact at the wire cross over points. One or more layers of this calendered mesh are then laminated under mechanical pressure in special fixtures inside a high temperature furnace. This furnace is filled with a proprietary inert gas atmosphere and the temperature is raised to a point where sintering (diffusion bonding) occurs.

After controlled cooling, the mesh has now become rigid by the bonding of the individual wires to each other and of each layer to the adjacent layer. Its comprehensive property is superior to sintered metal powder/granulate and porcelain.

|

Schematic overview sintered mesh |

The final product has an excellent strength. No inner support is required for making filter elements, cleaning is easy and long lifespans are possible. Common applied materials are stainless steel types 304L and 316L. More information on stainless steels can be found here: Stainless Steel Types. Exotic metals or alloys are also available on request. Filtration ranges from approx. 0,5 to 60 microns. The maximum size of a sintered woven wire mesh panel amount to approx. 500 x 1000 mm. Larger dimensions can be obtained by precision welding of panels.

|

Sectional view: sintered wire mesh (5 layers) |

|

frontview sintered mesh (5 layers partially on each) |

|

Front view: 2 layers sintered mesh in combination with perforated plate (support) |

(Gesinterd) geweven gaas kan ook gecombineerd worden met een non woven sintered web. Combinaties van deze materialen geven een filtratiebereik vanaf ongeveer 0,5 micron. Averinox levert filters of filtersegmenten toegesneden op uw specificatie, o.a. gebaseerd op gesinterd (geweven) gaas, zie Filter Elementen.

|

An example of 3 layer sintered woven mesh in combination with non-woven web |

Please contact us for more information on pressure drop and flow rates. More information, especially about common standard specifications and flow rates & pressure drop with different media, can be found partly on our Download Page.

top of page